13.3inch control box

QYTeco

| Availability: | |

|---|---|

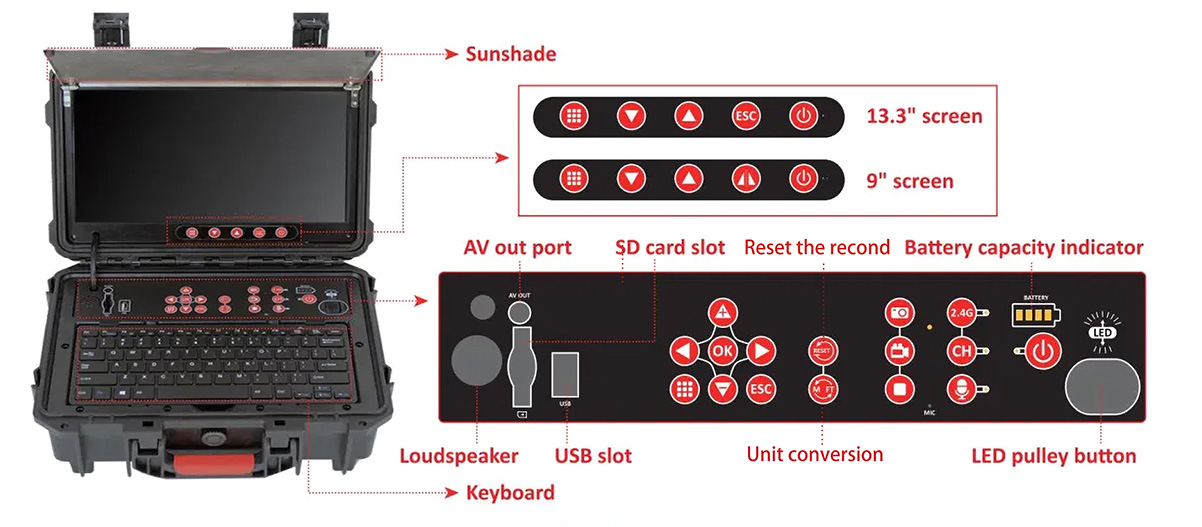

The 13.3 Inch Control Box serves as the command center for inspection systems, addressing the need for centralized, user-friendly control of camera heads, push rods, and data management. Its large 13.3-inch touchscreen display provides crystal-clear visualization of pipeline footage—critical for detailed defect detection—while robust storage and connectivity options ensure seamless data management (from recording to reporting). Unlike smaller control boxes, it offers enough screen space to display both live footage and inspection data (like depth, date, and location) simultaneously, reducing the need for multiple devices. Compatible with a wide range of camera heads (including 1080P pipe inspection cameras and the 29mm 150° Super Wide Viewing Angle Head) and push rods (like the 4.8mm Fiberglass Push Rod Cable Reel), this control box enhances efficiency in both field inspections (by streamlining operation) and post-inspection analysis (by simplifying report generation). Its rugged design also makes it suitable for harsh environments, from dusty construction sites to wet sewer treatment plants.

13.3 Inch Full HD Touchscreen: The display offers 1920×1080 resolution for detailed viewing of high-definition resolution footage, with multi-touch controls (pinch-to-zoom, swipe to pan) that make it easy to inspect specific areas of the pipe (like a small crack or joint). The touchscreen is also water-resistant (IP65-rated), allowing operators to use it with wet hands or in rainy conditions without damage. The screen’s brightness (600 nits) ensures visibility in both indoor and outdoor settings.

Expandable Storage: The control box supports up to 256GB microSD cards and USB drives (via two USB 3.0 ports), allowing continuous recording of inspections without memory constraints. The SD card slot is dust and water-resistant, ensuring data safety even in dusty construction sites or wet inspection environments. It also supports loop recording (overwriting old footage when the card is full) for long-term, unattended inspections.

Versatile Connectivity: Equipped with HDMI (for connecting external monitors), USB (for data transfer or charging), and Wi-Fi (2.4GHz and 5GHz bands), the control box enables real-time data sharing with remote teams (like engineers in an office), remote monitoring (via a smartphone app), and seamless report generation. Bluetooth connectivity is also included for pairing with wireless keyboards or mice—useful for typing notes during inspections.

Rugged Construction: The control box’s housing is made from impact-resistant ABS plastic (with a rubberized grip) and rated IP65 for dust and water resistance—protecting internal components from dust, water jets, and minor impacts (like being dropped from 1 meter onto concrete). The internal circuit board is also coated with a conformal layer to resist moisture and corrosion, ensuring reliable performance in humid environments (like sewer treatment plants).

Integrated Analysis Tools: The control box includes built-in software with on-screen measurement (to calculate defect size, like crack length or hole diameter), defect tagging (to label issues as “crack,” “blockage,” or “root intrusion”), and NASSCO-compliant coding (for standardized sewer inspection reports). This eliminates the need for third-party software, streamlining the process from inspection to client delivery.

This control box is indispensable for teams that require efficient, centralized inspection management:

Professional Inspection Teams: Managing multi-camera setups during large-scale municipal sewer projects (like citywide rehabilitation programs). The control box can connect to up to 4 camera heads simultaneously, allowing teams to inspect multiple pipes at once and share data in real time. It is also used by environmental agencies to monitor pipeline conditions and ensure compliance with regulations.

Industrial Maintenance Departments: Analyzing footage from factory pipelines (like chemical processing ducts or cooling lines) to plan preventive maintenance. The built-in measurement tools help engineers determine when pipes need to be replaced or repaired, reducing unplanned downtime. The Wi-Fi connectivity also allows maintenance teams to share footage with equipment manufacturers for expert advice.

Q: Is the control box compatible with third-party camera heads?

A: Yes, it works with most industry-standard cameras—including 1080P pipe inspection cameras with HDMI, RCA, or USB output. It also includes a universal adapter kit (with BNC, USB-C, and micro-HDMI connectors) for cameras with non-standard outputs, ensuring compatibility with older models or specialized cameras (like thermal imaging heads). The control box’s software automatically detects connected cameras and adjusts settings (like resolution or frame rate) for optimal performance.

Q: How does it handle low-light footage from cameras?

A: The built-in image enhancement software uses advanced algorithms to improve contrast and brightness in low-light footage, optimizing visibility of dark or underexposed areas (like deep sewer sections or pipes with minimal lighting). The software also reduces noise (graininess) in footage, ensuring high-definition resolution even in challenging lighting conditions. Operators can manually adjust contrast, brightness, and saturation via the touchscreen if needed.

Q: What power options are available for field use?

A: The control box operates on two power sources: AC power (via a 110V/220V adapter for indoor or vehicle-mounted use) or an optional 12V lithium-ion battery pack (sold separately). The battery pack provides up to 4 hours of portability for remote inspections (like rural sewer projects or areas without power access). It can also be charged via USB (using a portable power bank) for emergency power in the field. The control box also has a low-power mode that extends battery life by dimming the screen and disabling Wi-Fi when not in use.